Product Description:

Beauty and Skincare Custom Packaging Production Description

In the realm of beauty and skincare, custom packaging is not merely a container but a pivotal element that elevates brand identity, captivates consumers, and safeguards delicate products. Our production process seamlessly blends innovation, craftsmanship, and functionality to create packaging that harmoniously combines aesthetics and practicality.

Design Conception

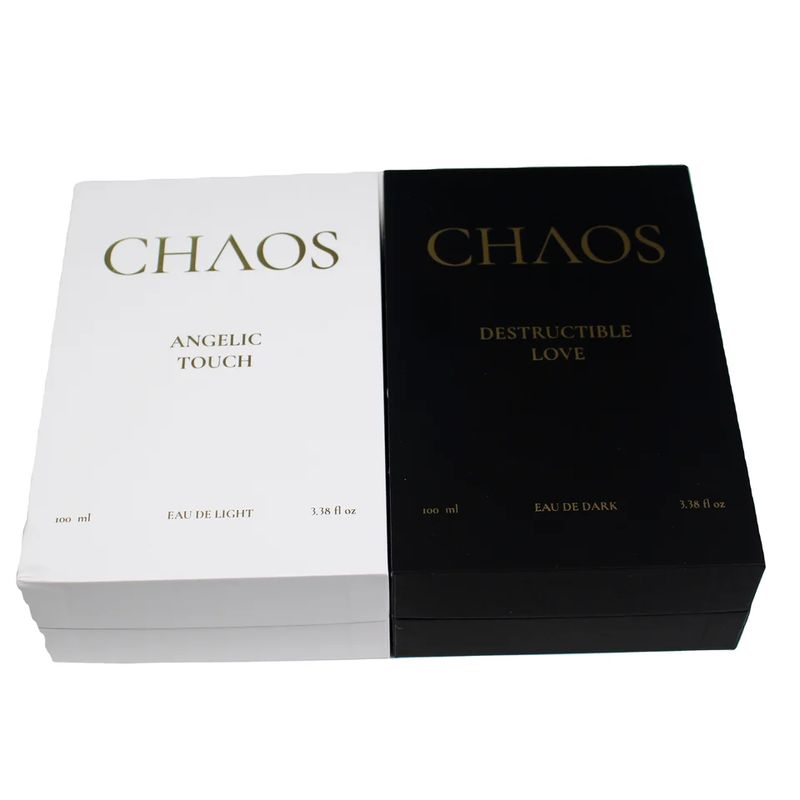

At the inception of the production journey, our team of seasoned designers collaborates closely with clients to distill their brand ethos, target audience, and product features into a unique design concept. We leverage the latest design software and tools to generate 2D sketches and 3D renderings, enabling clients to visualize the final packaging from every angle. Whether it's a minimalist, sleek design for a luxury skincare line or a vibrant, playful aesthetic for a beauty brand targeting younger consumers, our designs are tailored to resonate with the brand's essence and make a lasting impression on the shelf.

Material Selection

The choice of materials plays a crucial role in determining the quality, durability, and sustainability of beauty and skincare packaging. We source a diverse range of high-quality materials, including premium papers, eco-friendly cardboard, luxurious fabrics, and innovative plastics. For a touch of opulence, we offer materials like embossed leatherette, metallic-coated papers, and silk laminates. In response to the growing demand for sustainability, we also provide a selection of recycled, biodegradable, and compostable materials, ensuring that our packaging aligns with environmental responsibilities without compromising on style.

Printing Techniques

To bring the designs to life with exceptional clarity and color vibrancy, we employ state-of-the-art printing technologies. Offset printing is our go-to method for large-scale production, delivering sharp images and consistent color reproduction across a wide range of materials. Digital printing, on the other hand, offers flexibility for shorter runs and customized designs, allowing for quick turnaround times and the incorporation of variable data such as personalized labels. We also utilize advanced printing techniques like spot UV coating, which adds a glossy, raised effect to specific areas of the packaging, creating a striking contrast and enhancing the visual appeal.

Surface Finishing

The surface finishing of beauty and skincare packaging is where the true magic happens, transforming a simple box or bottle into a work of art. A plethora of options are available to add texture, depth, and a luxurious feel. Hot stamping, whether in gold, silver, or other metallic colors, imparts a touch of elegance and sophistication, highlighting brand logos and important product information. Embossing and debossing techniques create raised or recessed patterns, adding a tactile dimension that entices consumers to pick up the product. Lamination, available in glossy, matte, or soft-touch finishes, not only enhances the visual appeal but also provides protection against moisture, scratches, and wear.

Assembly and Quality Control

Once the individual components of the packaging are printed and finished, they are meticulously assembled by our skilled artisans. From folding and gluing boxes to attaching closures, inserts, and labels, every step is executed with precision and attention to detail. Before the final products are shipped, each piece of packaging undergoes a rigorous quality control inspection. We check for any defects in printing, finishing, or assembly, ensuring that only products of the highest quality reach our clients. Our commitment to quality extends to every aspect of the production process, guaranteeing that our custom packaging meets and exceeds expectations.

In conclusion, our beauty and skincare custom packaging production process is a comprehensive and collaborative endeavor that combines creativity, technical expertise, and a passion for excellence. By offering end-to-end solutions, from design to delivery, we empower beauty and skincare brands to stand out in a competitive market, leaving a lasting impression on consumers with packaging that is as exceptional as the products it holds.

Technical Parameters:

Lamination

Purpose: Enhance durability, moisture resistance, and visual appeal.

Types:

Gloss Lamination: High-shine finish, increases color vibrancy.

Technical: Polypropylene (PP) film applied via heat and pressure (100–130°C), thickness 1.5–3 mils (38–76 microns).

Matte Lamination: Smooth, non-reflective finish, reduces fingerprints.

Technical: Matte PP film, same thickness as gloss, the surface treated for low gloss (gloss unit <10).

Soft-Touch Lamination: Velvety, anti-scratch texture.

Technical: Specialized PE film with a micro-embossed surface, thickness 2–3 mils.

Applications: Luxury boxes, retail packaging, e-commerce cartons.

UV Varnish

Purpose: Highlight specific design elements or add protective coating.

Types:

Spot UV: Glossy coating on specific areas (e.g., logos, graphics).

Technical: UV-curable ink applied via screen printing, cured under UV lamps (365nm wavelength, 80–120W/cm).

Flood UV: Full-surface glossy/matte coating.

Technical: Roller-coating or flexo printing, cured in 1–3 seconds.

Textured UV: Embossed effect (e.g., leather, linen texture).

Technical: Special dies used during curing to create relief patterns.

Applications: Cosmetic boxes, greeting cards, premium product packaging.

Hot Foil Stamping

Purpose: Add metallic accents, luxury branding, or holographic effects.

Types:

Metallic Foil: Gold, silver, rose gold, copper.

Technical: Foil (aluminum or polyester-based) heated to 120–180°C, pressed via die onto cardboard (pressure 5–15 tons).

Holographic Foil: Iridescent, rainbow effect.

Technical: Pre-embossed foil with micro-layers, compatible with complex dies.

Cold Foil Stamping: Lower-temperature application (room temp), suitable for heat-sensitive materials.

Technical: Adhesive-based foil applied via flexo printing, no heat required.

Applications: Jewelry boxes, wine packaging, high-end retail boxes.

Embossing/Debossing

Purpose: Create tactile, three-dimensional designs.

Types:

Embossing: Raised texture on the surface.

Technical: Male/female dies (brass or magnesium) pressed at 80–120°C, pressure 10–20 tons, depth 0.3–1mm.

Debossing: Indented texture (reverse embossing).

Technical: Single die with a recessed design, often used for minimalist logos.

Blind Embossing/Debossing: No ink, pure texture effect.

Applications: Luxury brand logos, leather-textured boxes, premium paper goods.

Die-Cutting

Purpose: Create custom shapes, windows, or structural elements.

Technical:

Steel rule dies (for simple shapes) or laser-cutting (for intricate designs).

Tolerance: ±0.2mm for standard dies, ±0.1mm for laser-cutting.

Window Patching: Clear PVC/PET film glued into die-cut openings.

Applications: Product display boxes, shaped cartons, subscription boxes with inserts.

Coating

Purpose: Functional or decorative surface treatments.

Types:

Aqueous Coating: Water-based, matte/gloss finish, low VOC.

Technical: Applied via flexo printing, dried at 60–80°C.

Varnish Coating: Oil-based, durable gloss/matte finish.

Technical: Drying time 30–60 minutes, hardness 2–3H (pencil test).

Anti-Scratch Coating: Polyurethane-based, reduces abrasion.

Technical: Thickness 2–5 microns, scratch resistance ≥300 cycles (Martindale test).

Applications: E-commerce packaging (abrasion resistance), food packaging (FDA-compliant coatings).

Special Effect Techniques

Glitter Coating: Micro-glitter particles mixed with varnish for sparkle.

Technical: Particle size 50–200 microns, applied via screen printing.

Thermochromic Ink: Color changes with temperature (e.g., blue when cold, red when warm).

Technical: Activation temperature 22–31°C, reversible after cooling.

Flocking: Adhesive-backed fiber coating for soft texture (e.g., velvet).

Technical: Nylon/polyester fibers (0.1–0.3mm length) electrostatically applied.

Applications: Seasonal packaging, interactive designs, high-touch luxury boxes.

Technical Considerations for Cardboard Packaging

Substrate Compatibility:

Cardboard thickness: 200gsm–1500gsm (corrugated board).

Moisture content: 6–8% for optimal print/lamination adhesion.

Registration Accuracy:

For multi-process finishes (e.g., foil + embossing), registration tolerance ≤0.1mm.

Environmental Compliance:

FSC-certified cardboard, water-based inks, and recyclable laminates (e.g., PLA-based films).

Cost vs. Complexity:

Simple finishes (aqueous coating) cost $0.05–$0.20 per unit; complex finishes (foil + embossing + flocking) cost $1–$5 per unit.

Case Study: Luxury Skincare Box

Substrate: 1200gsm greyboard with 300gsm art paper laminate.

Finishes:

Matte lamination + spot UV on product imagery.

Hot foil stamping (rose gold) on brand logo.

Debossed ingredient list with blind embossing.

Die-cut window with PET film patching.

Technical Specs:

Print resolution: 300dpi CMYK + spot PMS colors.

Foil registration: ±0.05mm.

Embossing depth: 0.5mm.

Applications:

Product Protection and Preservation

Beauty products (creams, serums, fragrances) are often fragile, sensitive to light/moisture, or contain active ingredients that require stability.

Applications:

- Rigid Box Structures (e.g., magnetic closure boxes):

- Thick cardboard (600–1200gsm greyboard) with inner trays or inserts to secure glass bottles, jars, or palettes.

- Lined with foam, velvet, or EVA inserts for shock absorption (e.g., luxury skincare sets).

- Corrugated Mailer Boxes:

- For e-commerce shipments: Double-walled cardboard (B-F flute) with cushioning layers to prevent leaks or breakage during transit.

UV-Resistant Coatings:

- Boxes with matte/gloss lamination or UV varnish protect products from light degradation (e.g., vitamin C serums).

Brand Storytelling and Luxury Perception

63% of consumers associate packaging with brand quality. Custom boxes reinforce brand identity and justify premium pricing.

Applications:

- Embossed/Hot Foil Logos:

- Rose gold foil stamping on a midnight blue box for a luxury skincare line (e.g., Charlotte Tilbury).

- Blind embossing for minimalist brands (e.g., Glossier’s iconic pink boxes with subtle logo embossing).

- Thematic Designs:

- Seasonal collections (e.g., holiday-themed boxes with holographic foil or glitter coatings for brands like Sephora).

Customization:

Product Customization Services for the Beauty Packaging Box, Personal Care Packaging, and Cosmetic Container:

Product Name: Cosmetic Packaging Box

Place Of Origin: China

Certification: FSC

Minimum Order Quantity: 500 Pcs

Price: Negotiable

Packaging Details: Exporter Cartons And Pallets

Delivery Time: 10-15 Days

Payment Terms: T/T, Paypal, Western Union

Supply Ability: 2,000,000pcs /Month

Material: Coated Paper/White Cardboard/Corrugated Paper

Blank Sample: For Free

Colour: Custom

Print Way: Litho & UV Print

Support and Services:

Our Product Technical Support and Services for the Cosmetic Packaging Box include:

- Assistance with product assembly and usage

- Troubleshooting guidance for any issues

- Recommendations for maximizing the packaging box's functionality

- Information on maintenance and care

- Access to product updates and relevant resources

Packing and Shipping:

Product Packaging:

The Cosmetic Packaging Box is carefully designed to showcase your beauty products in an elegant and attractive manner. Made from high-quality materials, the box is sturdy and durable, ensuring that your cosmetics are well-protected during storage and transportation.

Shipping:

Our company takes great care in ensuring that your Cosmetic Packaging Box reaches you in perfect condition. We use reliable shipping services to deliver your order safely and promptly. Rest assured that your beauty products will arrive in pristine condition, ready to impress your customers.

FAQ:

Q: Where is the Cosmetic Packaging Box produced?

A: The Cosmetic Packaging Box is produced in China.

Q: What is the Certification of the Cosmetic Packaging Box?

A: The Cosmetic Packaging Box is certified by FSC (Forest Stewardship Council).

Q: What is the Minimum Order Quantity for the Cosmetic Packaging Box?

A: The Minimum Order Quantity for the Cosmetic Packaging Box is 500 pcs.

Q: What are the Packaging Details of the Cosmetic Packaging Box?

A: The Packaging Details of the Cosmetic Packaging Box include Exporter Cartons and Pallets.

Q: What are the Payment Terms accepted for the Cosmetic Packaging Box?

A: The Payment Terms accepted for the Cosmetic Packaging Box are T/T, Paypal, and Western Union.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!