Product Description:

Customizable Designs: At our company, we understand that each client has unique needs and tastes. That's why we work closely with our clients to create custom carton box designs that perfectly match their brand identity and product positioning. Our in-house design team can come up with unique structural designs, graphics, and finishes to help your packaging stand out.

High-Quality Materials: Our custom carton boxes are manufactured using a variety of materials, such as corrugated cardboard, rigid paperboard, and specialty substrates. No matter which material you choose, you can expect durability, strength, and visually appealing packaging.

Finishing Touches: We offer a range of finishing options to elevate the aesthetic appeal of your packaging. These options include foil stamping, spot UV coating, debossing, and embossing. These techniques can add a touch of elegance and sophistication to your carton boxes.

Flexible Sizing and Dimensions: We understand that our clients have different product requirements. Therefore, we can custom-design carton boxes in a wide range of sizes and dimensions to accommodate your specific needs. Whether it's a small retail item or a larger industrial product, we've got you covered.

Efficient Production and Rapid Turnaround: Our state-of-the-art manufacturing facilities and streamlined production processes allow us to deliver custom carton boxes with a fast turnaround. We know time is of the essence, so we work hard to ensure your products reach the market on time.

Sustainable and Eco-Friendly Options: For clients interested in environmentally conscious packaging solutions, we offer eco-friendly alternatives such as recyclable and biodegradable carton box materials. We understand our clients' sustainability goals and strive to offer solutions that align with them.

Competitive Pricing: By leveraging our extensive industry experience and economies of scale, we're able to provide clients with competitive pricing on our custom packaging carton boxes. You'll get great value for your investment.

Technical Parameters:

Material Specifications:

Substrate type:

The substrate type refers to the material that will be used to make the box. This could be corrugated cardboard, rigid paperboard, linerboard or any other material that would be suitable for the intended purpose of the box.

Grammage or thickness of the material:

The grammage or thickness of the material used is an important factor in determining the strength and durability of the box. The thicker the material, the stronger the box will be.

Strength and durability properties:

The strength and durability of the box will depend on various properties such as the material used, the thickness, the design, and the intended use. It is important to choose a material and design that will be strong enough to protect the contents of the box during transport and storage.

Printability and surface finishes:

The printability and surface finish of the box will depend on the type of printing technology used and the design requirements. It is important to choose a substrate that will be suitable for the intended printing method and finish.

Structural Design:

Box style:

The box style refers to the way the box is designed and manufactured. This could be a tuck-top, flip-top, sleeve, two-piece or any other style that would be suitable for the intended purpose of the box.

Dimensions (length, width, height):

The dimensions of the box will depend on the contents that need to be packaged. It is important to choose dimensions that will be suitable for the intended contents and use.

Opening and closure mechanisms:

The box should be designed with an opening and closure mechanism that will be suitable for the intended purpose and contents. This could be a flap, a lid, a sliding mechanism or any other suitable method.

Interlocking features for stacking or display:

The box could be designed with interlocking features that will allow for ease of stacking and display. This could be in the form of tabs or slots that will allow for a secure fit.

Ventilation or perforations (if required):

If the contents of the box require ventilation or perforations, the box should be designed with suitable features that will allow for adequate airflow.

Printing and Graphics:

Printing technology:

The printing technology used will depend on the design requirements, the material used, and the printing budget. The printing technology could be offset, flexographic, digital or any other suitable method.

Color options and ink coverage:

The color options and ink coverage will depend on the design requirements and the printing method used. It is important to choose suitable colors and ink coverage that will be visually appealing and cost-effective.

Graphic design elements:

The graphic design elements could include logos, text, images or any other design elements that will be suitable for the intended purpose and use of the box.

Special finishing techniques:

Special finishing techniques could include foil stamping, embossing, spot UV or any other suitable method that will enhance the visual appeal of the box.

Functionality and Performance:

Load-bearing capacity and stacking strength:

The load-bearing capacity and stacking strength of the box will depend on the material used, the design, and the intended use. It is important to choose a material and design that will be strong enough to support the intended contents and stacking requirements.

Moisture and water resistance:

Moisture and water resistance could be required if the contents of the box are sensitive to moisture or water. The box should be designed with suitable features that will help to prevent moisture or water damage.

Insulation or temperature control (if required):

If the contents of the box require insulation or temperature control, the box should be designed with suitable features that will help to maintain the required temperature and prevent heat loss or gain.

Tamper-evident or security features:

If the contents of the box require tamper-evident or security features, the box should be designed with suitable features that will help to prevent unauthorized access or tampering.

Ease of assembly and product insertion/removal:

The box should be designed to be easy to assemble and to allow for easy insertion and removal of the contents.

Sustainability and Compliance:

Use of eco-friendly, recyclable, or biodegradable materials:

The use of eco-friendly, recyclable, or biodegradable materials is important for sustainability and minimizing the impact on the environment. It is important to choose materials that are sustainable and environmentally responsible.

Compliance with industry regulations and standards:

The box should be designed to comply with industry regulations and standards for safety and quality.

Minimization of waste and carbon footprint:

The box should be designed to minimize waste and reduce the carbon footprint. This could be achieved by using sustainable materials, optimizing the packaging design, and reducing excess packaging.

Production and Logistics:

Minimum order quantity (MOQ) requirements:

There may be minimum order quantity requirements for the production of the box. The MOQ will depend on the manufacturing process and the intended use of the box.

Lead time for manufacturing and delivery:

The lead time for manufacturing and delivery of the box will depend on various factors such as the design, the materials used, and the quantity required. It is important to plan ahead and allow sufficient time for production and delivery.

Packaging options for shipping and storage:

The box should be designed with suitable packaging options for shipping and storage. This could include flat-pack options, palletization, or any other suitable method for efficient storage and transportation.

Customization and personalization capabilities:

The box could be designed with customization and personalization capabilities to make it more unique and appealing to consumers. This could include personalized branding, color options, or any other suitable method.

Testing and Quality Assurance:

Rigorous quality control measures:

The box should be subject to rigorous quality control measures to ensure that it meets the required safety and quality standards.

Performance testing:

The box should be subject to performance testing such as drop testing and compression testing to ensure that it can withstand the intended use and shipping requirements.

Adherence to industry standards and certifications:

The box should adhere to industry standards and certifications for safety, quality, and environmental responsibility.

| Box Dimensions: |

Length: ___________ cm/inches |

| Width: ___________ cm/inches |

| Height: ___________ cm/inches |

| Material Type and Thickness: |

Material: 2mm Chipboard |

| Thickness: 2mm |

| Printing Design and Artwork: |

Artwork files format:PDF/AI/PS/CDW |

| Resolution: 300 DPI |

| Color Mode: PMS/Pantone/CMYK |

| Specific artwork requirements: Outlined the fonts |

| Structural Design: |

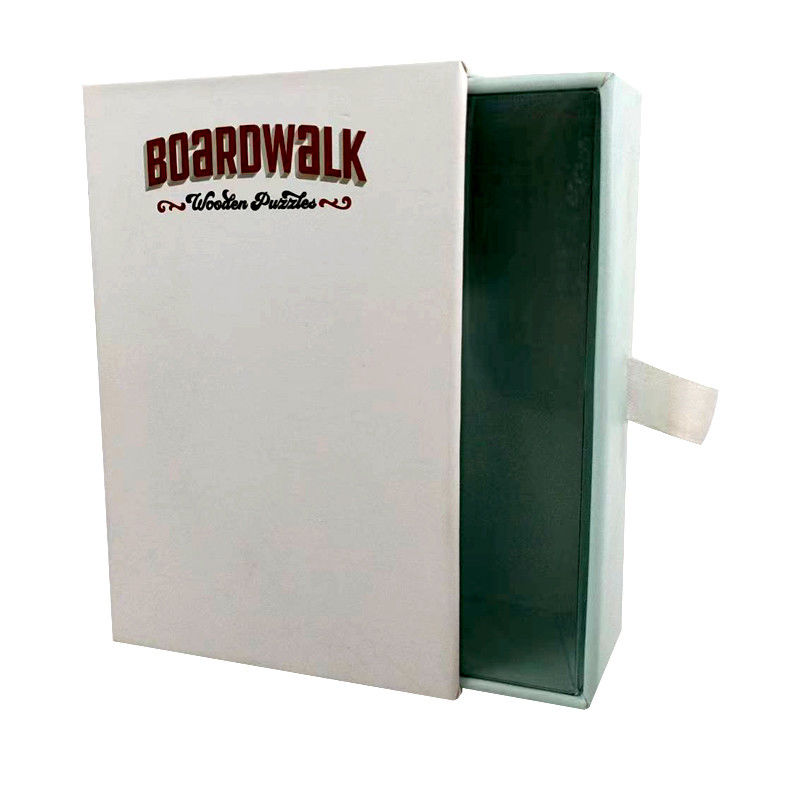

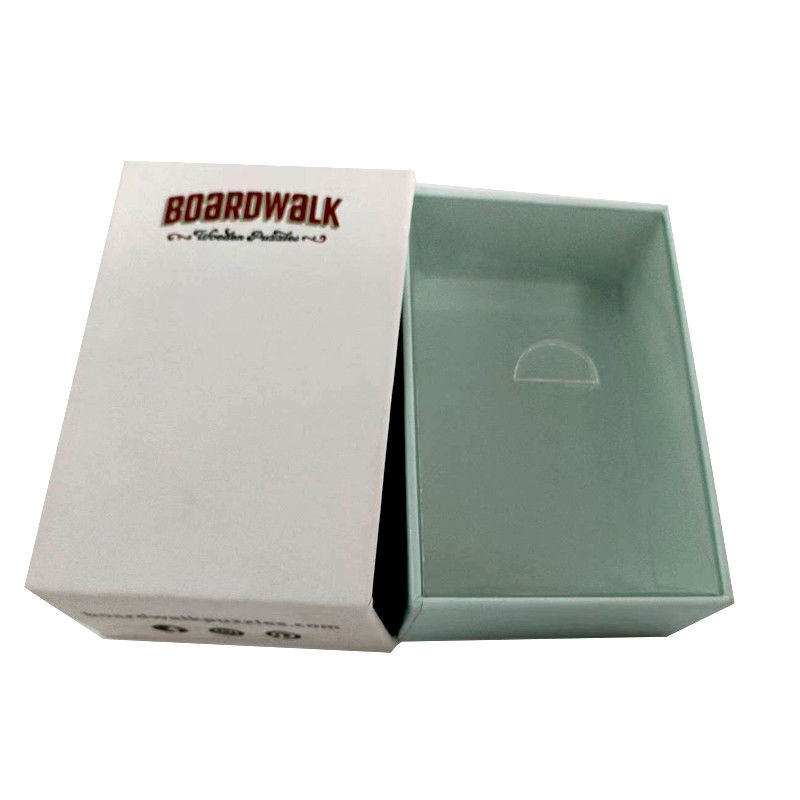

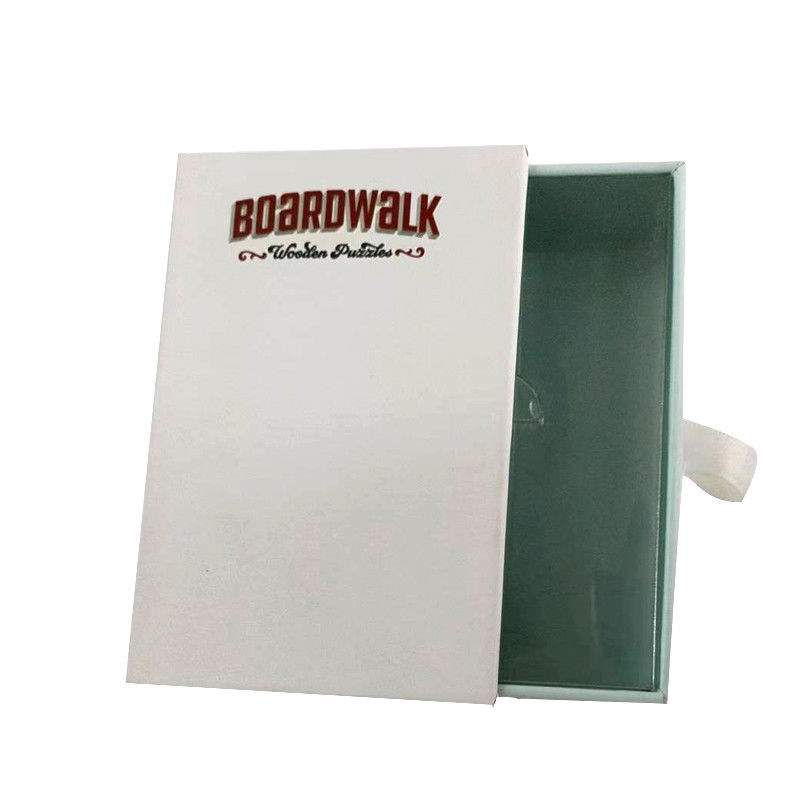

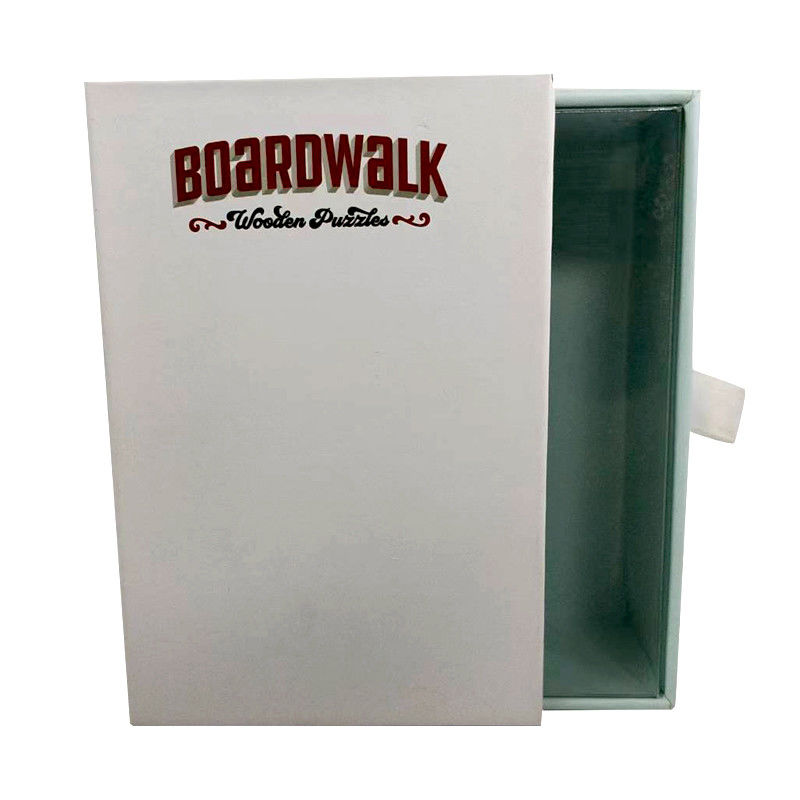

Box Style: Sliding with Drawer |

| Closure Method: Ribbon |

| Additional Features: As Required |

| Box Strength and Weight Capacity: |

Desired strength: Custom Requirements |

| Weight capacity: 0.5 kg/lbs |

| Surface Finishes and Coatings: |

Finish Type: Matt/Glossy PP/ |

| Coating Type: AQU Vanishing |

| Additional Finishing Requirements: |

| Golden Foil Stamping, UV Coating/ Emboss/Deboss |

| Sustainability Considerations: |

Eco-friendly materials |

| Sustainable manufacturing practices |

| Testing and Prototyping: |

Testing requirements: As Required |

| Prototyping requirements: As Required |

Applications:

Whether it's for retail, food, cosmetics, or any other industry, CKT's packaging solutions are versatile and customizable. The company offers free packaging design services to ensure that your product stands out on the shelves.

CKT's packaging boxes come in different structures, including flat and stand-up. You can also choose from various handle options, such as PP rope, cotton rope, ribbon, etc. The packaging boxes are available in different colors, including CMYK, Pantone, etc. You can also have your logo embossed or debossed on the packaging box.

The CKT packaging boxes are FSC/SGS certified, ensuring that the packaging materials used are sustainable and eco-friendly. The exporter cartons and pallets used for packaging details also comply with international standards to ensure safe transportation of the products.

The delivery time for CKT's packaging solutions is 10-15 days, and the company offers various payment terms, including T/T, Paypal, and Western Union. The price for the packaging boxes is negotiable, and the supply ability is 2,000,000pcs per month.

If you're a small business owner looking for cute packaging boxes for your products, CKT's packaging solutions are an excellent option. The customizable design, sustainable materials, and versatile structures make them ideal for any small business looking to enhance its product packaging and branding.

Customization:

Support and Services:

Custom Packaging Solutions provides technical support and services to ensure the optimal performance of our products. Our team of experts is available to assist with any inquiries or issues related to our packaging solutions. Whether it's troubleshooting, training, or maintenance, we are committed to providing our customers with reliable and timely support to ensure their packaging needs are met. Contact us to learn more about our technical support and services.

Packing and Shipping:

Product Packaging:

Our custom packaging solutions are carefully packaged to ensure they arrive at your doorstep in excellent condition. We use high-quality materials and proper cushioning to protect your products during transit.

Shipping:

We offer fast and reliable shipping options to ensure your custom packaging solutions arrive as quickly as possible. We work with trusted carriers to provide affordable and efficient shipping to our customers.

FAQ:

What is a Cardboard Paper Drawer Box?

A cardboard paper drawer box is a type of storage container made from rigid paperboard or corrugated cardboard. It features a drawer-like design that slides in and out, allowing easy access to the contents inside. These boxes are commonly used for organizing, storing, and transporting a variety of items.

What are the Main Materials Used for Cardboard Paper Drawer Boxes?

The most common materials used for cardboard paper drawer boxes are:

Solid Paperboard - A thick, single-ply paperboard material.

Corrugated Cardboard - Made with a wavy inner layer sandwiched between two flat outer liners.

Recycled Cardboard - Manufactured using recycled paper fibers for greater sustainability.

What are the Key Benefits of Cardboard Paper Drawer Boxes?

Sturdy Construction - Paperboard and corrugated cardboard provide strength and durability.

Modular Design - Drawer boxes can be stacked or arranged in different configurations.

Customization - Boxes can be printed with graphics, labels, or branding.

Cost-Effective - Cardboard materials are generally inexpensive to produce.

Lightweight - Cardboard boxes are easy to move and transport.

Sustainable - Many options are made from recycled materials.

How are Cardboard Paper Drawer Boxes Manufactured?

The typical manufacturing process involves:

Paperboard/Cardboard Production - The raw materials are formed into the desired sheet or roll.

Printing & Finishing - The surfaces may be printed, coated, or laminated as needed.

Die-Cutting - The cardboard is cut into the specific drawer box shapes and sizes.

Assembly - The pieces are folded, glued, or locked together to create the final drawer box.

What are Common Uses for Cardboard Paper Drawer Boxes?

Cardboard paper drawer boxes are commonly used for:

Office & Desk Organization

Craft & Sewing Supplies Storage

Hobby & Collections Organization

Household Item Storage

Retail Merchandise Display

Shipping & Transportation

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!